The Horse and Buggy Days

Two brothers, William and August Timpte arrived in the Mile High City sometime around 1880, just a few years after Colorado became the 38th state of the union. Trained in their father’s blacksmithing shop, the Timpte boys first went to work for the railroad in the booming, young frontier town. As Denver grew, so did its transportation needs, and William and August Timpte set up separate companies in 1884. The August Timpte Wagon and Carriage Works and the Wm. Timpte Carriage Works were soon busy supplying and repairing delivery wagons, buggies and carriages.

After a few years running separate operations, the brothers decided to merge their two shops into one company, The Timpte Brothers Wagon Company. The new operation was established in 1891 and moved to a 12,500 square foot plant at 2300 Market Street in Denver where they remained for the next 50 years. Timpte Brothers became the largest vehicle supplier in the Mountain states, and was busy designing and manufacturing buggies, carriages, light spring wagons for mining, commerce and local delivery, and heavy brewery wagons. After over 30 years of building their young company the founders, William and August Timpte, retired. Their sons, T.C. “Tony” Timpte and C.A. “Clem” Timpte took over in 1916 to enter the beginnings of the age of motorized transport.

Evolution of the Motor Truck

Tony and Clem, the second generation of Timpte’s to steer the company, took over management at about the same time that American transportation evolved from the horse to the combustion engine for power.

The company’s skills and manufacturing facilities were quickly transformed from wagons to bodies for the early motor chassis. Among the first products was a delivery body built on a Model T chassis. Farm bodies, local delivery vans and highway transports followed. By the 1920’s people needed to be moved too, and Timpte Brothers responded by manufacturing school bus and bus line bodies for truck chassis. Milk wagons, many types of agricultural bodies, sugar beet bodies and stake beds were added to the product line. The craftsmanship in this era was expanded to cover ambulance and hearse bodies, local delivery and van bodies, dump bodies and even utility bodies.

Timpte’s first semi-trailer was produced in 1931 and was set on a chassis furnished by Fruehauf. Thus was born the age of the semi-trailer, the major product line which is still the backbone of the company today. The company began making trailer chassis by 1938. The new trailer chassis incorporated a spring and hanger suspension assembly originated and designed by Timpte. Improvements and more sophistication were being built into the bodies that were mounted on the new chassis. It was becoming more evident that the semi-trailer method of transportation was going to become an integral part of the modern freight system. Van installations on truck chassis were becoming more common and Timpte redesigned construction to use steel in place of wood. This foresight made Timpte the largest supplier of truck mounted van bodies in the Rocky Mountain area.

The War Years

By 1940 Timpte Brothers had become a large manufacturing and service facility for transportation and was bursting at the seams in the Market Street plant. This location was built for horse-drawn wagons and was no longer adequate. As the clouds of war swept over Europe, Clem and Tony Timpte were busy building a modern new service and manufacturing facility in Northeast Denver at 40th and York. A publication soon after the move in 1941 described the new 56,000 square foot plant as – “Of ultra-modern construction, 90% of its wall space is devoted to big steel-sash windows through which streams abundant sunlight. The building stands on a ground area of four acres, assuring plenty of easy parking. The Plant throughout is equipped with the latest type mechanical and electrical equipment … welding, power, lighting, and precision machinery. Management continues to feature its Personal Service … all Sales and Shop Supervision are under the personal care of T. C. and C. A. Timpte themselves.” This new plant was over four times as large as the Market Street plant and was put into operation just before the United States became involved in World War II.

Timpte’s plant and people were wholly devoted to the war effort and 95% of the production in these years was under government contract. Trailers of many types were manufactured and shipped to Europe and other theatres of war. Among units purchased by the Army were textile and shoe repair trailers, laundry trailers, flatbeds for hauling equipment and communication trailers. Timco refrigeration units were installed on bodies and trailers and used to get fresh food to our fighting men. Timpte’s outstanding efforts in this period earned the company the Army-Navy “E” Award for the excellence of production.

Timpte Emerges Into Modern Company

At the end of the war years, Tony Timpte bought out his cousin Clem and the company was incorporated as Timpte, Inc. This era saw manufacturing modernized, the product line narrowed to trailers, truck bodies, and sleeper cabs, and the beginnings of the company that personifies the Timpte companies today. The Timpte sleeper cab was a big seller nationally until 1960, when inventive truck makers began installing them on the trucks.

No sooner had steel replaced wood, than aluminum for bodies and trailers entered the trucking industry. Without the knowledge and tooling to work with this new material, Tony Timpte was not about to lose his reputation as an innovator. Until aluminum production facilities were obtained and refined, Timpte made trailers by buying kits from Reynolds Aluminum Company and assembled them onto chassis made by Timpte.

The entire Rocky Mountain region was growing after the war and Timpte joined this expansion by opening a branch manufacturing and service facility in Albuquerque, New Mexico in 1947. In 1952, this facility was expanded to 21,000 square feet on 4 acres.

The 1950’s brought forth further innovations in products for the transportation industry. Timpte designed and built farm truck bodies and trailers, steel van bodies, package delivery walk-ins and of course, refrigerated and dry semi-trailers.

Another Timpte innovation in the early 1950’s was the evolution of light weight steel trailers. A 35 foot flatbed was designed utilizing high tensile T-1 steel which weighed less than 9,000 pounds. Even in the earlier days, the desire of the motor carriers was to own and operate lighter equipment. In 1948, Timpte designed a frameless trailer constructed of steel saving approximately 2,000 pounds in tare weight. These were some of the first trailers that incorporated the frame into the side construction. This design allowed the deletion of the chassis frame to reduce tare weight.

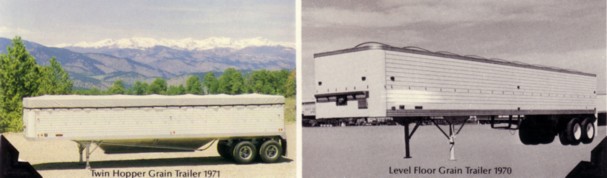

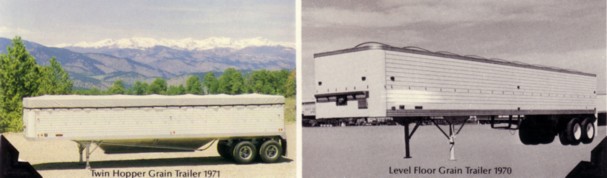

The first level floor grain trailer was made in 1953. In 1948, Timpte began manufacturing large cattle trailers for the booming Midwest livestock industry. A second manufacturing shift was added and production was again increased.

By 1959 the York Street plant was inadequate for Timpte’s needs. Designed 20 years earlier for service and manufacturing, there wasn’t enough room for storage, parking, and for manufacturing the new, longer trailers. Twenty acres of land was purchased at 59th and Washington Street in Denver for this relocation. The new 132,000 square feet of plant was completed in January of 1961.

Tony Timpte was in failing health during the construction of the new plant and made the decision to sell the company to Ohio Brass Company of Mansfield, Ohio in the fall of 1960. After devoting almost 50 years of his life to Timpte and the transportation industry of America, Tony Timpte died in May of 1961.

Timpte Ownership Returns to Denver:

Expansion and Merger Years

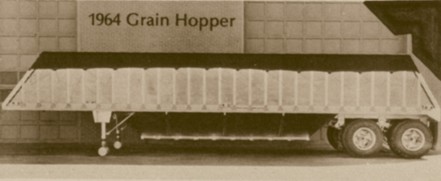

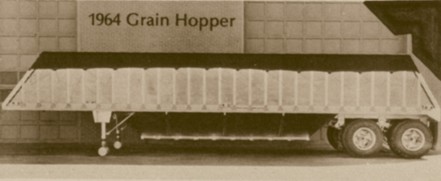

Under the ownership of Ohio Brass, Timpte continued to grow and prosper. The grain hopper trailer was developed in 1963 and the modern refrigerated trailer was developed when the company received an order for 50 trailers from Pacific Fruit Express in 1964. However, the original concept Ohio Brass had in mind in acquiring the company from Tony Timpte did not work out, and being uncomfortable in the trailer business, Ohio Brass decided to sell the Timpte division.

To forestall acquisition by another company, a group of employees and friends led by Timpte officers, Bob Ruland, Jim Lakin, Ray Bissell, and Tom Gamel formed a new corporation to buy the Timpte division from Ohio Brass. In April of 1966 this group bought the assets of Timpte and continued the operation under new ownership, but the same management.

A new subsidiary, Tyco, Inc. was formed by the new Timpte Company in 1967 to assist their customers in financing of new trailers. By 1968, a decision was made to move the service and parts facility into a separate location at 5701 Dexter in Denver, which coincidentally was the facility occupied by Beall from 1957 to 1968. A major Timpte plant production reorganization was completed in 1969 and manufacturing capacity and efficiency were greatly improved.

At this time it was decided that production and sales would be concentrated on refrigerated and grain trailers, but a full line of dumps, bottom dumps, lowboys, and flats were still being produced.

Timpte Industries, Inc. was formed in 1970 when Timpte, Inc. acquired Alumacraft Marine Products Corporation of Minneapolis. Alumacraft, founded in 1946 as a division of Flour City Ornamental Iron Works Company, was a pioneer in the manufacture of aluminum fishing boats. After prospering for many years, the division was sold in 1960 to Hupp Corporation of Cleveland. The manufacture of fiberglass boats was added in 1961. In 1962 Alumacraft was acquired by Alpex Corporation. Alumacraft went public in January, 1969. Alumacraft then purchased two mobile home manufacturers: Tourite, of Fort Worth in March 1969, and Gordonay, of South Carolina in December 1969.

Timpte Industries thus became a holding company, owning four corporations – Timpte, Alumacraft, Tourite, and Gordonay. Because of losses, Alumacraft discontinued the manufacture of fiberglass boats, and Gordonay was liquidated in November 1970. Timpte Industries sold a new common stock issue of 240,000 shares to the public in September 1971. The stock was subsequently listed on the American Stock Exchange in September 1972.

Alumacraft continued to grow and needed larger manufacturing facilities. A new plant was put into operation in St. Peter, Minnesota, in February 1972, and the Minneapolis facility was sold.

Further actions in 1972 saw Timpte, Inc. selling the sales and service branch in Albuquerque, and opening new sales branches in St. Paul, Minnesota, and Council Bluffs, Iowa.

Timpte-Beall, Inc., a major acquisition for Timpte Industries, was formed in March of 1973 to acquire the assets of Beall Equipment of Colorado. Beall Equipment’s history dated back to 1905 and had a long and varied story.

After several name changes, Beall Pipe and Tank Corporation emerged in 1925 and the company began its Colorado activities in 1957. Beall Equipment of Colorado was a pioneer in the manufacture of frameless aluminum tank semi-trailers. The manufacturing location was in Henderson, Colorado, and was first operational in 1968, with 53,000 square feet on nine acres.

Columbia Corporation of Portland acquired The Beall Tank and Pipe Company and its subsidiaries in 1970. Timpte Industries then acquired the Colorado operation by forming Timpte-Beall in March, 1973. Timpte-Beall was sold in 1983.

Current Era – Nebraska

The era of the Super Hopper began in May 1980, when Timpte opened a new 55,000 square foot manufacturing plant on 28 acres in David City, Nebraska devoted entirely to the manufacture of grain trailers. This plant was built in the Midwest grain belt to be closer to the customers.

In May 1985, Timpte started construction of a modern 170,000 square foot refrigerated trailer manufacturing plant in Wayne, Nebraska. This plant had a new, unique manufacturing process for manufacturing modular trailer panels. This plant was opened in April 1986 and the Denver plant was closed in 1986 and sold later that year.

In October 1988, Timpte sold the refrigerated trailer business and the Wayne plant (which still operates today) to competitor Great Dane Trailers. The decision was to concentrate on aluminum grain trailers in David City and Ken Allred was made President of this operation.

Timpte made significant additions to the David City Plant in 1985, 1992, 1994, 1996,1998, 2002, 2005, 2008, 2010, and 2013.

In 2008, Dale Jones was hired as CEO and President of Timpte, replacing Ken Allred who retired after 30 years of loyal and successful service. In 2009, Timpte celebrated its 125th Anniversary with an Open House at David City.

The equipment in the David City, Nebraska plant is state-of-the-art and the plant produces a high quality product very efficiently. A superior engineering staff make what the customer wants.

Timpte sells its product directly and through a network of independent dealers. Timpte’s seven sales and service branches [Council Bluffs, Iowa; Urbana, Iowa; Aurora, Nebraska; Princeton ,Illinois; Bloomington, Illinois; Sioux Falls, South Dakota; and Mankato, Minnesota] contain a total of 71,000 square feet on 39 acres. The Company also has sales only offices in De Forest, Wisconsin; Mt. Pleasant, Iowa; and Sioux City, Iowa. They are strategically located to best serve the customers’ trailer needs.

Today Timpte is the market leader in aluminum bulk commodity trailers, referred to as grain trailers The plant in David City which began with 55,000 square feet on 28 acres is now 195,000 square feet on 43 acres.

See www.timpte.com for more information

Mrs. B

Mrs. B